Four major R&D pathways

Four major R&D pathways

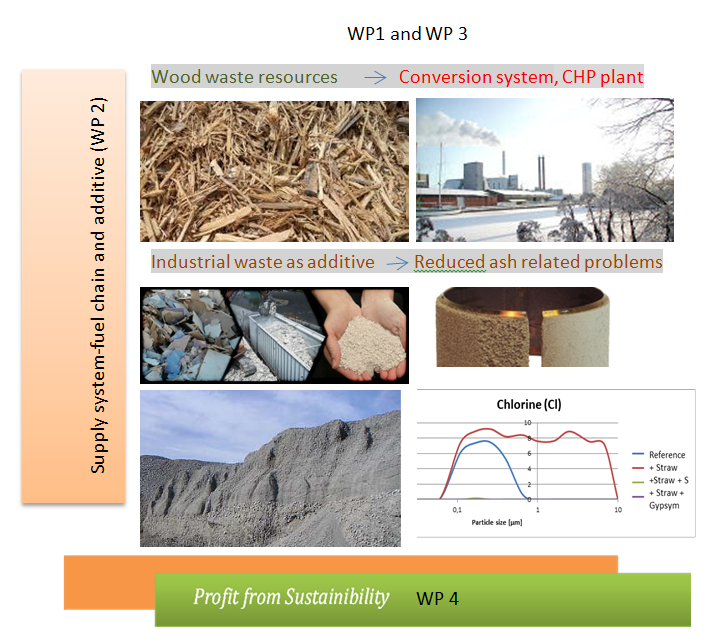

Fundamental research, applied research and innovative full scale trials will be developed throughout REFAWOOD project work activities. REFAWOOD will identify and create new opportunities to improve economic and environmental conditions and enlarge the market for the use of wood waste fuels in heating- and CHP-plants by using resource efficient additives such as recycled gypsum during combustion. The REFAWOOD Consortium will focus the work on four major R&D pathways as illustrated in Figure 1.

Figure 1: The four major R&D pathways

Five work packages

The REFAWOOD project consists of the following five work packages:

WP1 Fuel additive design concepts for reduction of ash related problems in wood waste combustion

WP1 will deal with fundamental research on ash transformation processes including bed agglomeration, slagging and fouling and high temperature corrosion. The influence of new cheap and resource efficient fuel additives on important ash transformation processes in fluidized- and fixed bed combustion of wood waste will be determined. The research will be performed on lab scale as well as bench scale fluidized- and fixed bed equipment’s, and supported by thermochemical modelling. WP1 will serve WP3 with input of full-scale experimental operation conditions including interesting fuel-additive blending concepts.

WP2 Supply system and utilization of ash -The fuel and additive value chain

WP2 involve case studies that show how resource efficient additives can be integrated with the fuel chain and blended within the fuel in a technical/ economical way. Further how use of additives can increase both plant reliability and the number of load hours of the CHP plants and how it affects the maintenance and operational costs as well as to propose ways to utilize the ashes from the combustion plants in an environmentally and economically efficient manner. These cases will be based on the full scale trials in WP 3.

WP3, Full-scale trials in heating and CHP plants

In WP3, Full-scale trials in heating and CHP plants are conducted with a fuel mix containing waste wood chips and additives in a biofuel-fired CHP plant in four participating countries, based on the results of WP1 (fuel-additive blending concepts)) the effect of the additive is studied with respect to particle composition of the fine particles (<1 micron), fouling/high temperature corrosion, slagging and emissions (including SO2 and HCl). The CHP/heating plants in each country have different size, technology, fuelled with different types of wood waste (from recovered wood to low quality forest waste) and the trials will therefore complement each other.

WP4 Analysis of sustainability of the value chain

WP4 Analysis of sustainability (economic, environmental and social) of the value chain, will build on the results of WP2 and WP3 by doing a full-scale environmental life cycle assessment (LCA), evaluating the environmental benefits and impacts of gypsum board and sulphide ore utilisation, combined with a life cycle costing (LCC) study. These assessments will be carried out using as much as possible site-specific data from the case studies, and will analyze on the one hand the effects of avoided land-filling and on the other the effects of changing emission from biomass combustion, based on the data from WP2 and WP3. Finally, a quantitative analysis of the overall EU potential for use of these residue streams for (waste) wood combustion will be carried out, including a qualitativesocio-economic assessment.

WP5 dissemination and exploitation of results

In WP5 dissemination and exploitation of results will be performed. Information about the project results will be communicated to the public via a project webpage. To disseminate the project results to a broad public, an international workshop will be organised at the end of the project. Stakeholders from the participating countries will be invited.